Aftertreatment Process

1. Waterproof and oilproof treatment

Wet dusty gas can moisten and bond the dust (particularly water-absorbing & deliquescent dust) gathered on the surfaces of filter bags, even blur the bags, which is the most unacceptable result for bag filters. Therefore, the filter cloth should be subjected to waterproof and oilproof treatment to ensure that every single fiber is hydrophobic and oleophobic and increase the surface tension of filter materials, which can effectively combine the condensed water drops and dust into beads and prevent them from blocking the filtration capillary channel after the permeation into the filter materials, thus avoiding the phenomenon of bag blurring caused by condensation.

2. Teflon ® coating treatment

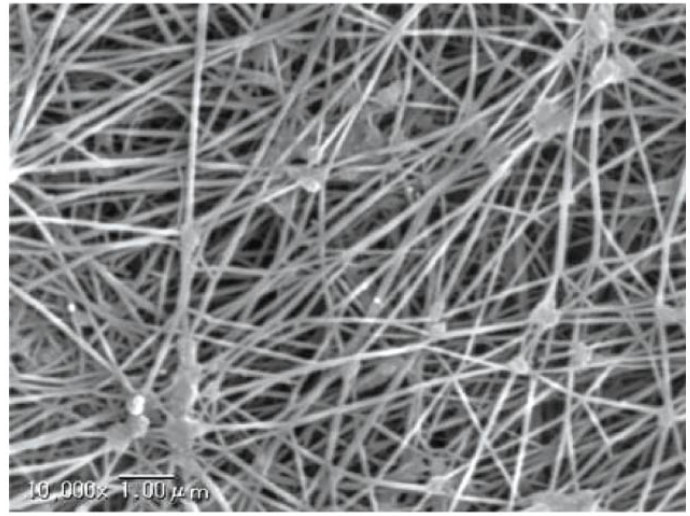

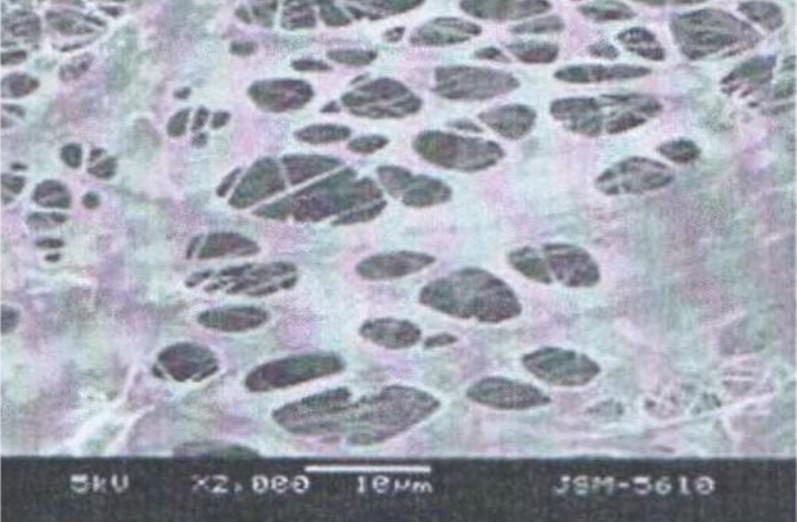

When the diameter of the dust is less than 1um or the dust has higher viscosity or the gas has higher humidity, common filter materials cannot effectively filter the dust. The microporous thin-wall composite filter material taking PTFE (Teflon ®) as a raw material has extremely high filtration accuracy and a smooth surface, cannot be adhered to the dust, and can easily remove the dust without making the dust permeate into itself, realizing surface filtration.

PTFE thin-wall scanning electron micrograph (*1,000)

3. Fiber plating treatment

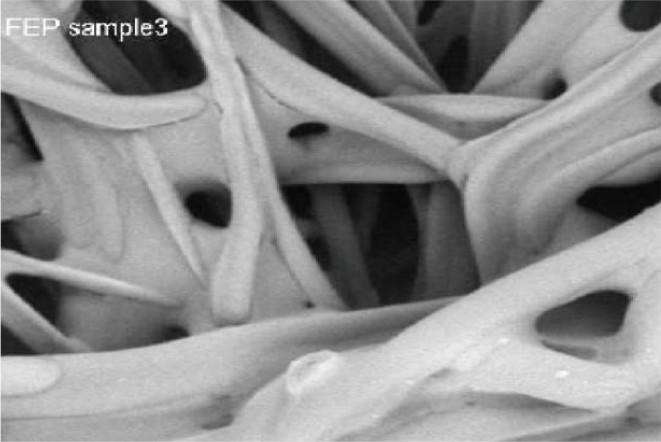

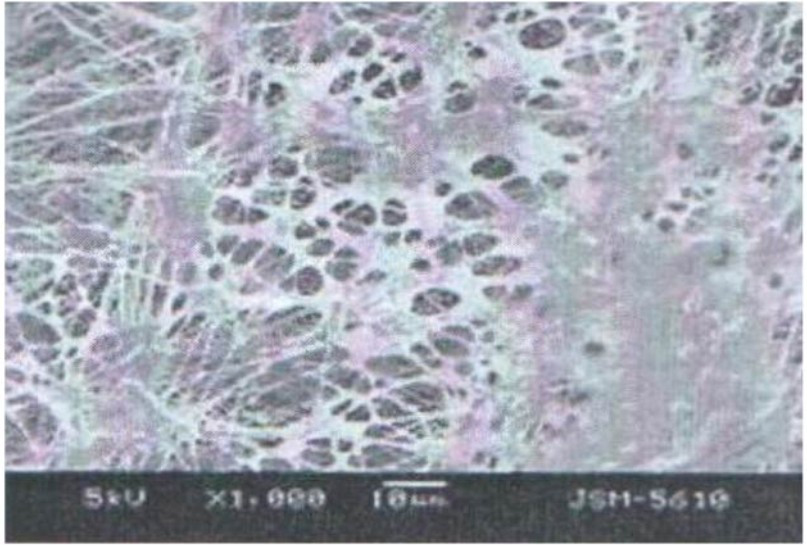

Our plating emulsion, a high-concentration PTFE emulsion, adopts a dedicated formula developed by JH in combination with leading technical formulas in various large same industries of the world, to carry out integral plating treatment on the punched felts. PTFE dispersion plating treatment can well protect the fibers of the filter materials, improve the corrosion resistance, oxidation resistance and temperature resistance of the fibers and enhance the hydrophobicity of the filter materials, thus prolonging the service life of the filter materials, and improving the filtration accuracy of the filter materials at the same time to ensure that the filter materials can adapt to severer operating environment.

PTFE-B fiber plating treatment process electron microscope observation diagram

4. Intumescent coating treatment

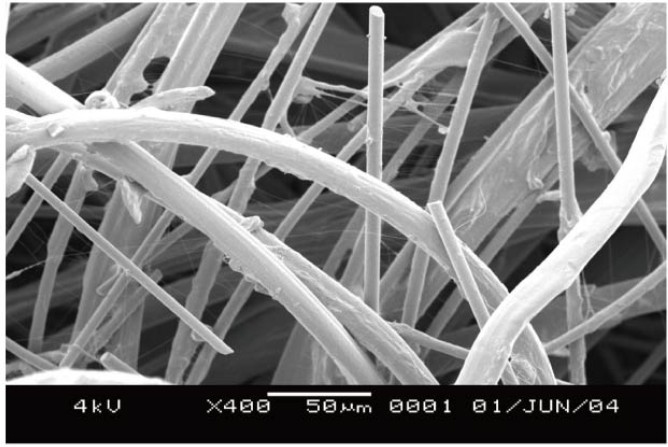

High-temperature-resistant high-performance filter materials obtained by coating Teflon-B emulsion on the surfaces of filter materials and carrying out drying, heat setting and other conventional processes can greatly improve the oxidation resistance, corrosion resistance, folding resistance and temperature resistance of the filter materials, improve the dust removing effect and enhance the hydrophobicity of the filter materials, ensuring that the filter bags cannot be hardened and pasted at a higher water content; meanwhile, the filtration accuracy of the filter materials is improved, and the service life of the filter materials is prolonged.

Intumescent coating technology

5. Easy dust removing treatment

The grinding performance of dust is related to the properties and forms of dust particles, the airflow velocity of the carried dust particles, dust concentration and other factors. The grinding performance of irregular particles with rough surfaces and sharp prism shapes is 10 times higher than that of particles with smooth surfaces. The dust particles with the diameter of about 90um have the highest abrasiveness, while their abrasiveness is extremely low when the diameter is reduced to 5-10um. Aluminum powder, silicon powder, carbon powder, sintering mineral powder and other kinds of powder belong to high-abrasiveness dust. The grinding dust must be removed by the filter cloth which has high abrasion resistance and can easily handling the dust. Carrying out easy dust removing treatment on the surfaces by silicon oil graphite, PTFE resin, etc., the abrasion resistance and folding resistance of the filter materials can be improved.

6. Singeing and calendaring treatment

Dust particles can be attached to other dust particles or can contact with the surfaces of other objects. When contacting with each other, suspended dust particles are mutually adsorbed and coagulated. The cohesion of dust is related to types, shapes, diameter distribution, moisture content, surface characteristics and many other factors of dust particles, and can be represented by the angle of repose (generally 30°-45°). When the angle of repose is less than 30°, the dust is low in cohesion and high in mobility, which must be removed by the filter materials of which the surfaces are singed, to improve the surface area of the filter materials, increase the collection rate of the filter materials on the dust, and facilitate in blowing the dust out from the deep parts of the filter materials during dust removal; when the angle of repose is larger than 30°, the dust is high in cohesion and low in mobility, which must be removed by the filter materials of which the surfaces are calendered, to improve the surface smoothness of the filter materials, increase the collection rate of the filter material surfaces on the dust, and eliminate dust removal difficulties caused after the dust enters the deep parts of the filter materials.

- Pre:Production Process 2016/10/9

- Next:None